Rubber air spring

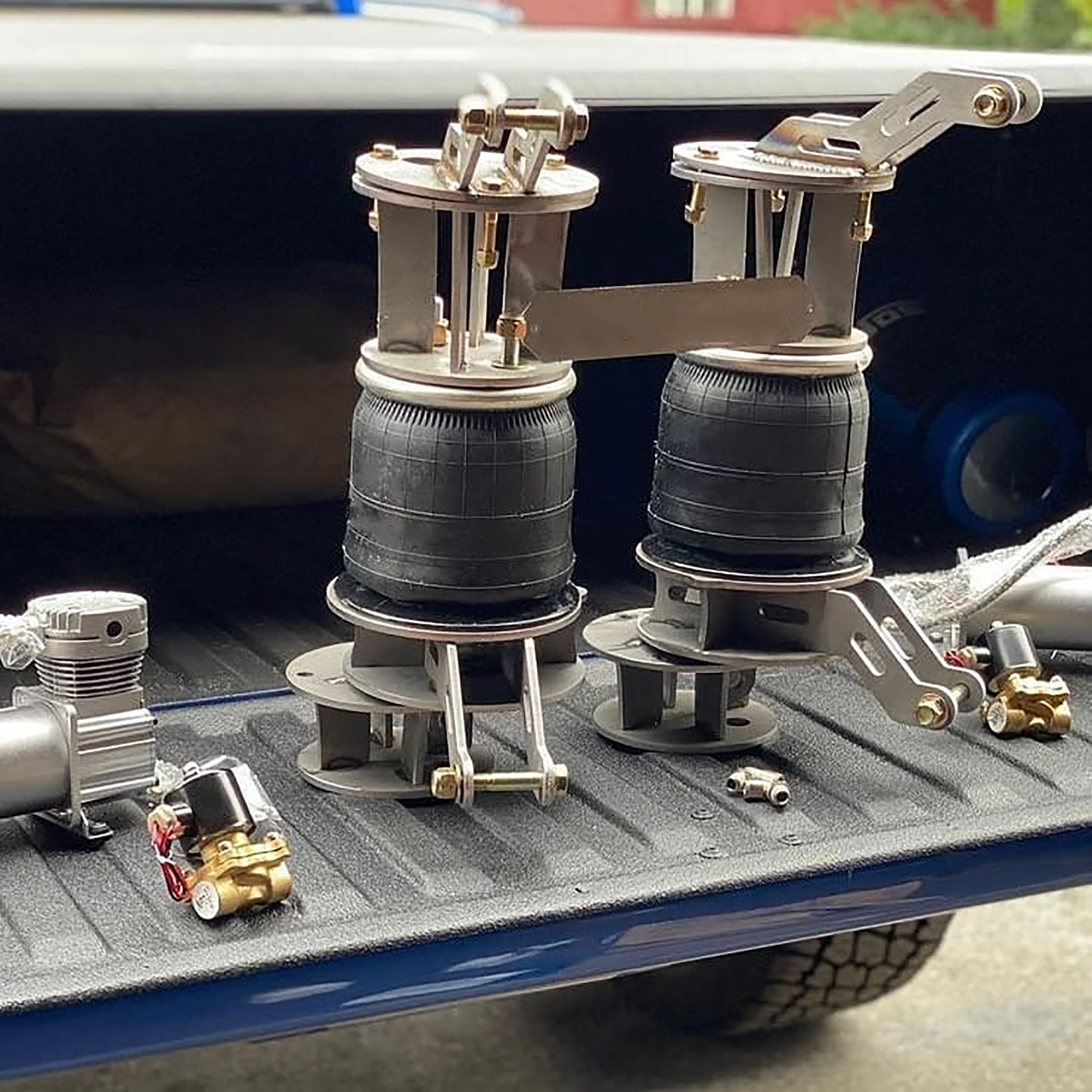

The rubber air spring is a curved capsule made of rubber and mesh wire, commonly known as air tire, corrugated air tire, air bag, leather tiger, etc. The two ends of the capsule need to be connected with two steel plates to form a compressed air chamber. The rubber and mesh wire themselves do not provide load-bearing capacity, but the compressed air filled in the capsule completes it. The number of curved capsules is usually 1~3, but it can also be designed and manufactured into 4 or 5 curves or more according to needs, and two air springs can be stacked and used under certain conditions.

According to performance and characteristics, it is also called: rubber air stroke regulator, rubber air vibration isolator, two names, rubber air springs are divided into three categories according to shape: capsule type, membrane type and sleeve type. According to the sealing structure, it is divided into four categories: pressure self-sealing type, wheel rim clamping type, hoop sealing type and hybrid type. The load of the rubber air spring is mainly borne by the cord, and the number of cord layers is mainly composed of 2 layers. Special requirements products are composed of 4 cord layers. The inner layer of rubber mainly plays a sealing role, and the outer layer of rubber plays a protective role in addition to sealing.

The end structures of existing curved bladder rubber air springs can be divided into three categories according to the connection method: one is a fixed flange connection type, in which the edge dimensions of both ends of the air spring are equal to or slightly smaller than the maximum outer diameter of the curved bladder, and after drilling several holes, they are fastened and connected with flange rings and end plates; the other is a slip-on flange connection type, in which the edge dimensions of both ends of the air spring are much smaller than the maximum outer diameter of the curved bladder, and no holes need to be drilled, and they are fastened and connected with a special flange ring and an ordinary end plate; the third is a self-sealing type, which does not require flange connection, is pressed into the end plate, and seals itself when compressed air is filled.